Key Takeaways

- Samsung’s new tech recovers 80% of QD ink waste, saves $7.3 million yearly

- Recycling course of maintains authentic ink high quality

- No drastic modifications in QD-OLED panel improvement

Samsung has announced a model new expertise to assist mitigate the waste in quantum dot (QD) ink. It is a core aspect of the manufacturing of Samsung’s QD-OLED panels. Having the ability to recycle discarded ink might lead to lowered prices whenever you buy your next display.

Samsung Display makes use of ultra-fine semiconductor particles often known as quantum dots (QD) for a lot of of its shows. This manufacturing course of sadly comes at a price of loads of wasted and discarded ink. Nevertheless, the corporate introduced that it is developed a brand new type of quantum dot ink recycling expertise that can “improve the price competitiveness of its QD-OLED shows.”

Associated

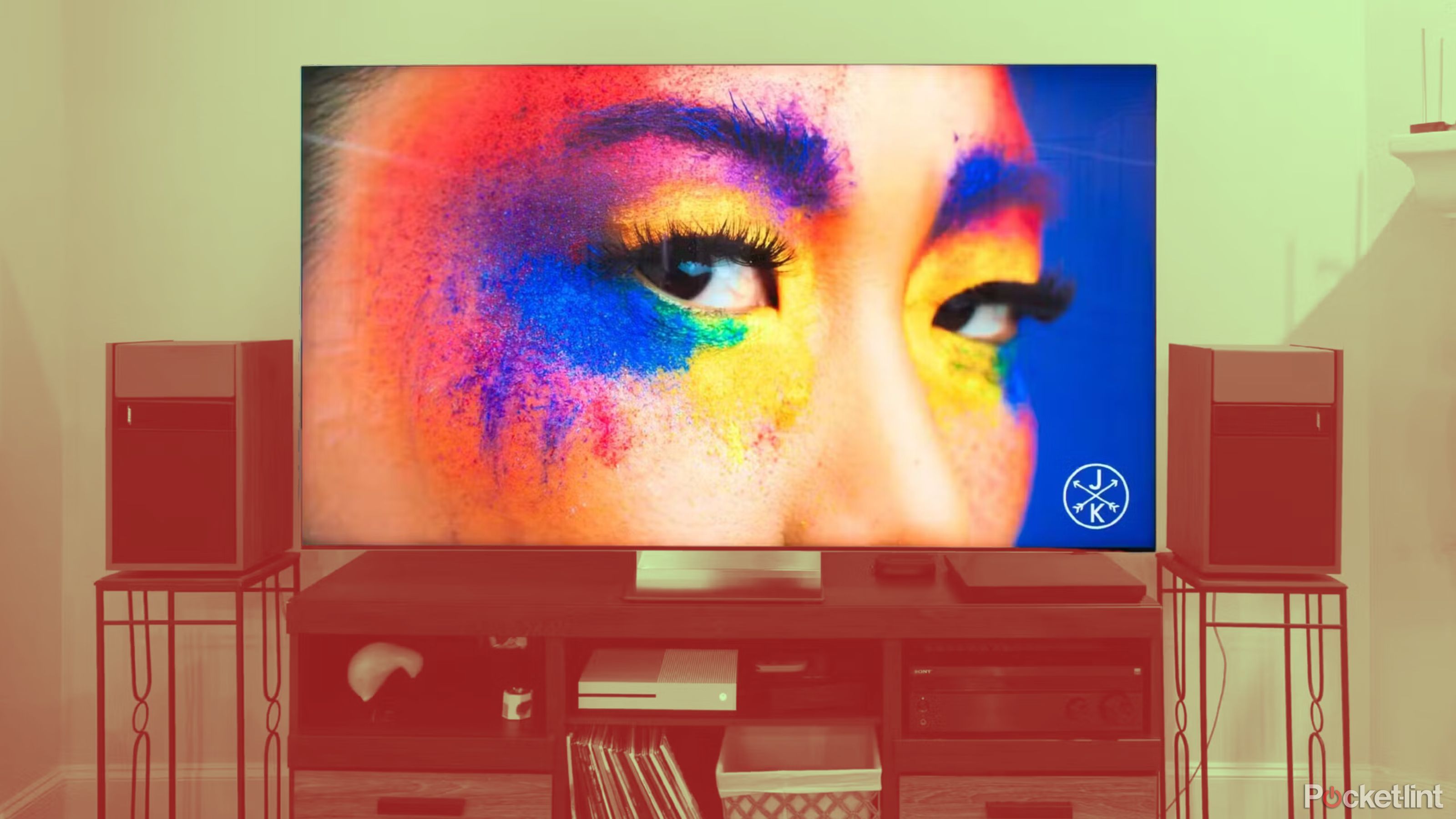

The Samsung S95D is a stunning OLED model for 2024

The Samsung S95D is the highest of the road OLED mannequin from Samsung for 2024. It gives a blinding picture with unbeatable distinction and wealthy coloration depth.

Samsung’s new expertise recovers 80 p.c of in any other case misplaced QD ink

With a significant discount in losses, annual price financial savings could also be over $7.3 million

Samsung

Samsung S90D

- Model

- Samsung

- Show Dimension

- 55-inches

- Working System

- Tizen OS

- Show Kind

- QD-OLED

- Show Decision

- 4K

Samsung introduced that the brand new expertise can acquire and recycle QD ink that’s usually wasted throughout the QD-OLED manufacturing course of. The QD layer in its shows is made utilizing an inkjet course of that sprays crimson and inexperienced QD ink into tiny micrometer-sized nozzles. Up till lately, 20 p.c of the ink used ended up caught within the nozzles and was finally discarded. That ends in a ton of wasted QD ink and sources over the yr.

Samsung’s new recycling course of can recuperate and reuse as much as 80 p.c of that wasted product. In accordance with Samsung, having the means to recuperate this quantity of QD ink all through the method might lead to annual financial savings of KRW 10 billion (roughly $7.3 million USD). These financial savings can then be used to assist offset shopper prices when the QD-OLED panels hit retailer cabinets.

Associated

I’d buy a mini-LED TV before an OLED TV for these 6 reasons

The longer term is brilliant for mini-LED TVs — they’re holding their very own with spectacular colours and high quality distinction in opposition to OLED screens.

What’s the distinction in Samsung’s QD-OLED course of?

Samsung is not reinventing the wheel on the subject of the event of its panels

Samsung

As Samsung confirms, the brand new QD ink course of is not drastically altering the best way it develops its QD-OLED panels. Samsung Show assembled a process power led by the BP expertise crew. Their objective was to develop a QD ink recycling facility in August, which they succeeded in doing. The collected ink undergoes an analogous superior synthesis expertise course of that “revives its purity and optical properties.”

The corporate confirms that the ink collected maintains the “identical efficiency ranges as the unique ink in high quality exams.” In reality, it has been in use on the manufacturing line since October.

Associated

I’m picking Samsung over LG for my next OLED smart TV — here’s why

The variations could also be slight, however this is the reason Samsung takes the win as my subsequent OLED sensible TV.